Contact info

E-mail Us:

Requesting A Call

Location Here

6, Eastern Park

Kolkata - 700086

Kolkata - 700086

All would require a couple of months to see the above—mentioned effects from (1)to(3), however,it will be found shortly if there has actually been the effect(4)

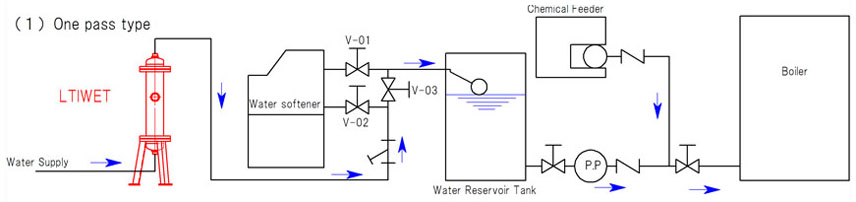

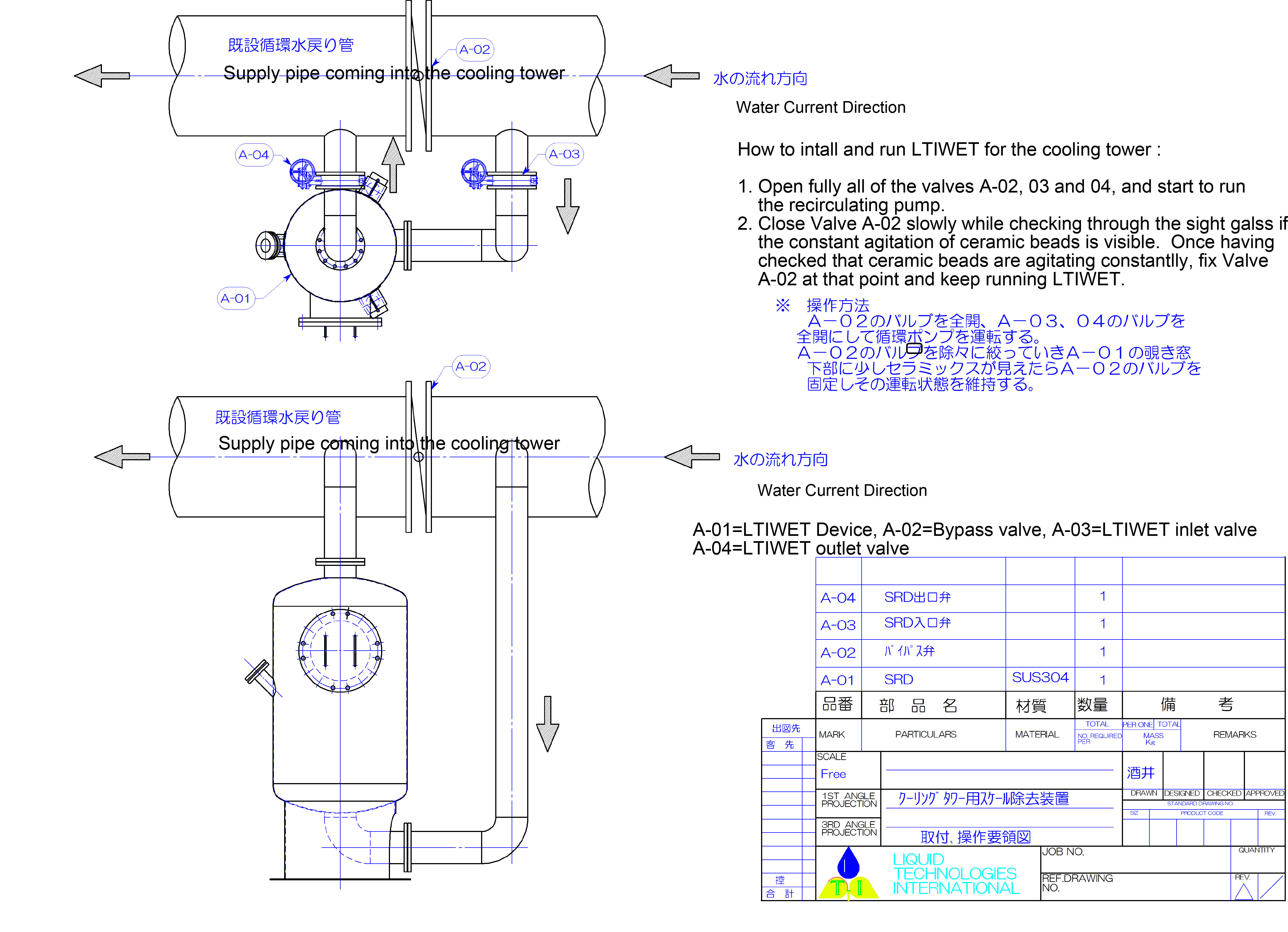

In the case of one pass type,cIose valve V—03,and open valve V—01.V—02. Once the water softener has been found to be unnecessary due to no scale formation,open valve V—03,and close valve V—01,V—02.

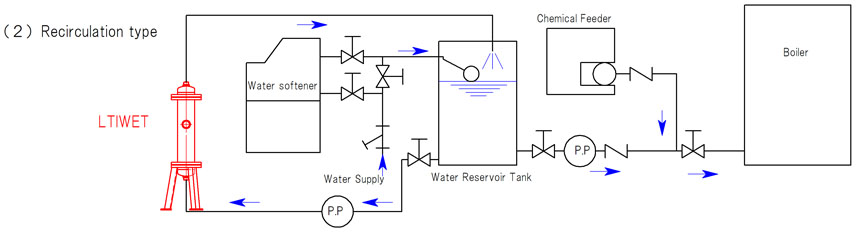

This installation of LTIWET should be possible without changing the existing water flow but just installing LTIWET after the water softener.

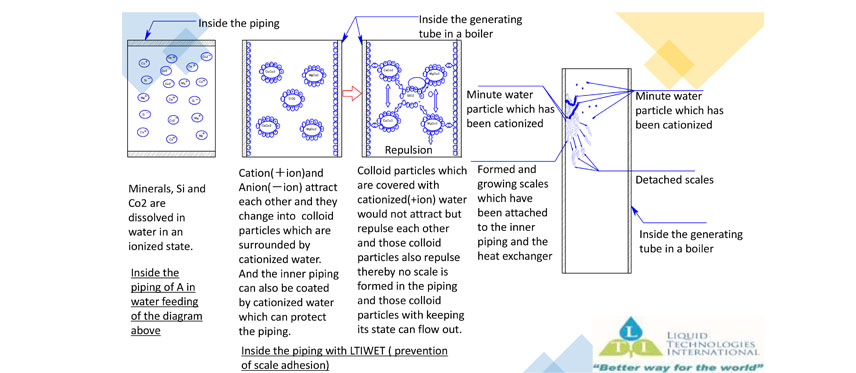

Water particle which has gone through LTIWET ( SRD ) has become so tiny and minute compared with water particle before going through LTIWET ( SR D) , and also the surface tension of such water which is cationized and of which particle is so minute and thereby such cationized water can easily penetrate into some spaces of scales which have been bonded by crystals of a variety of arbonates including CaCO3 and MgCO3 so that bonding between scales become looser and those scales can be scrapped off and detached naturally without any force or device. Such a process is repeated and scales which have been stuck to the inner tube of a boiler will disappear gradually.

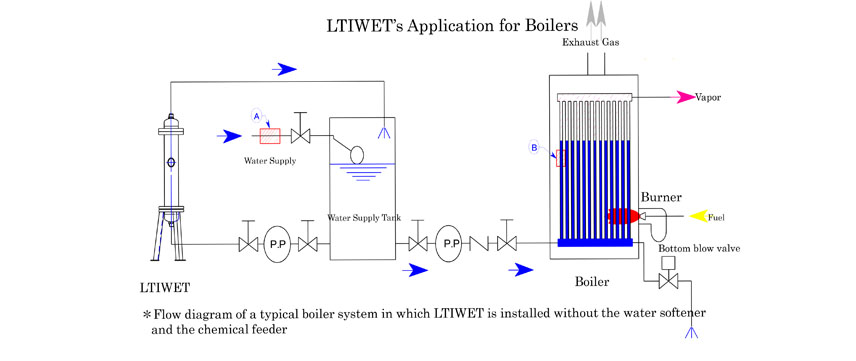

The water goes into a boiler which is heated with burner flame and it will change into steam which will get out of the boiler at some fixed pressure. As a matter of course, steam going out of a boiler does not include any ionized minerals so the boiler water will be concentrated gradually and scales will start to attach to the pipeline once such concentration of water reaches the limit. To avoid such issues in the conventional system, the softener is installed at the water supply line and hardness component is absorbed and removed by the ion exchange resin. However, such ion exchange resin will cease to be effective in absorbing hardness component unless it is cleaned by back washing with salty water. In addition to the cleansing process above, other processes including scale removal and prevention of corrosion using the boiler compound and deoxygenating agent need to be conducted while the concentrated boiler water needs to be discharged from the bottom blow valve on a periodical basis. Regardless of such processes being conducted, the quantity of scales attached to the pipeline will increase unless the periodical cleansing process for the pipeline is made consistently. The installation of LTIWET would make it possible for none of the above-mentioned process of cleansing including back washing and chemical feed to be required, which can lead to less maintenance efforts and the cost reduction. However, blow down process of the concentrated water should of course be required.

*Not all of the recirculating water. Makeup water is always added.

The total quantity of circulating water (L/min.) x 5% x 5

In the above example : 1,300L/min. x 5% x 5 = 325L/min.

The trial for the cooling tower can be conducted as illustrated in the first page.

With the installation of the device, water in the tank can be recirculated going through the device at multiple times a day. Please note this trial should be easy one: just a submerged pump should be required and nothing in the existing line is required to be changed so this trial can be accepted by your customers easily.

For less than 200RT(TR) of the capacity, W3 model should be recommended for the trial.

Between over 200RT( TR) and 400RT (TR), W5 model should be recommended for the trial.

For more than 500RT(TR), W7 model should be recommended for the trial.

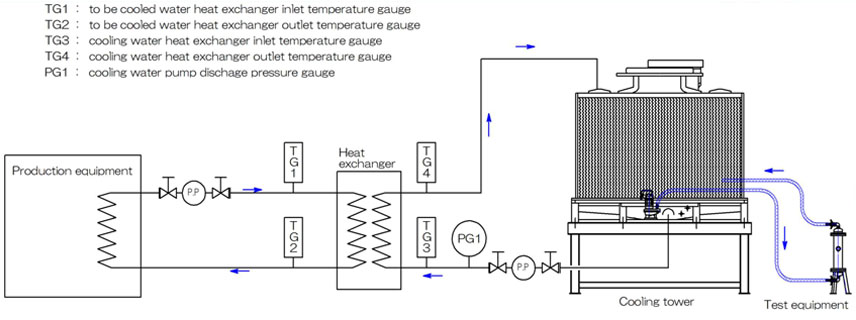

If the cooling tower can be stopped for a while and the heat exchanger can be opened, open the heat exchanger before starting the trial and again open after 10 days, 20 days and 30 days and check if the heat exchanger is started to be cleaned.

If the cooling tower cannot be stopped and is required to run for 24 hours, then the temperature difference can be criteria for judging the effects of LTIWET device.

1)Check the temperature difference between TG1 and TG2, also between TG3 and TG4 before the installation of LTIWET device.

2)Check the temperature difference between TG1 and TG2, also between TG3 and TG4 after the installation and running of LTIWET device after 10, 20 and 30 days respectively

NB: The outside air temperature in the comparison above should be similar, and if a little scale is built up in the heat exchanger, the temperature difference could be much less.

Expanding the temperature difference mentioned above could show the effects that the heat exchanger has been cleaned up and the existing scales have been removed.