Contact info

E-mail Us:

Requesting A Call

Location Here

6, Eastern Park

Kolkata - 700086

Kolkata - 700086

*Not all of the recirculating water. Makeup water is always added.

The total quantity of circulating water (L/min.) x 5% x 5

In the above example : 1,300L/min. x 5% x 5 = 325L/min.

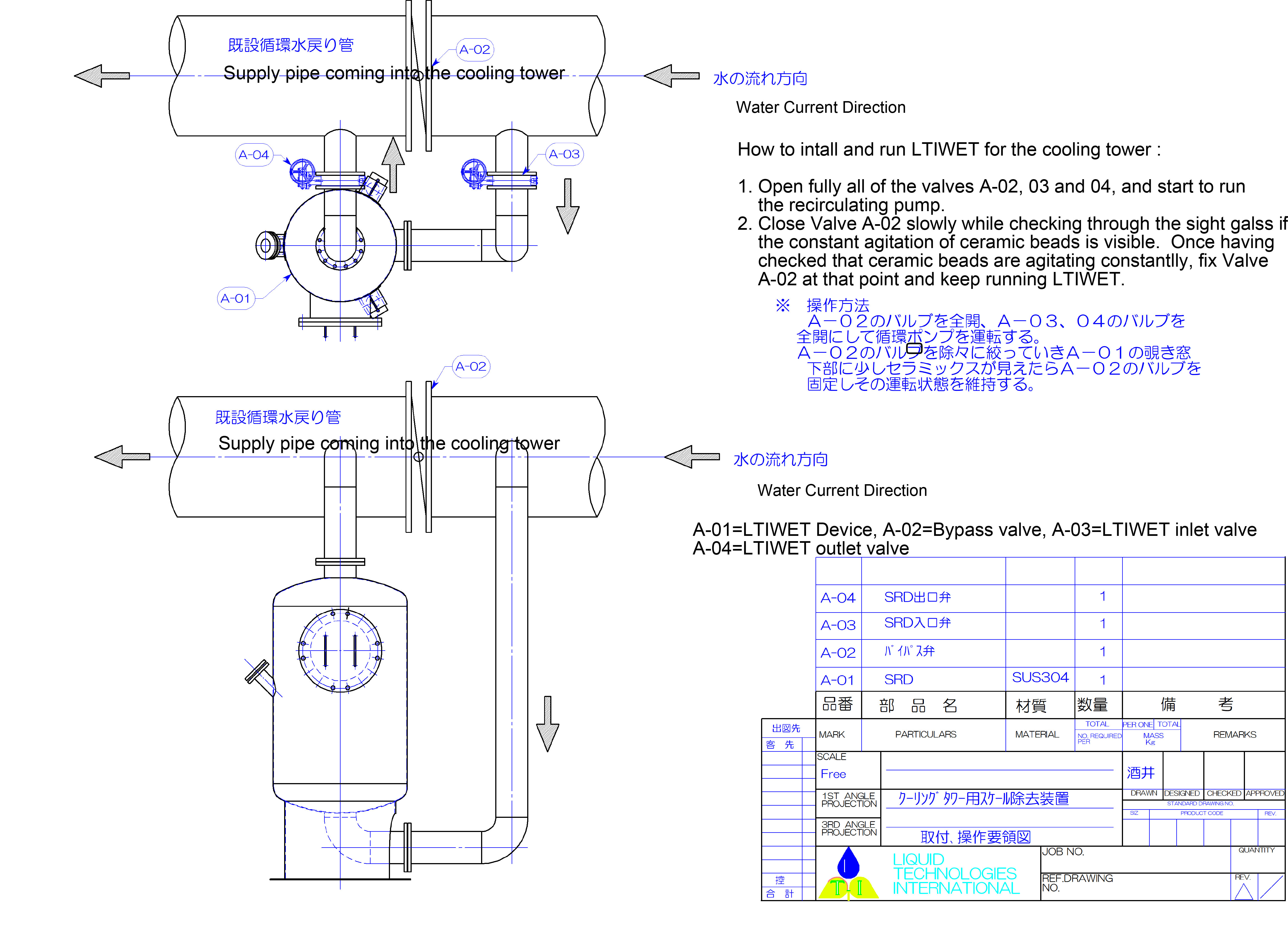

The trial for the cooling tower can be conducted as illustrated in the first page.

With the installation of the device, water in the tank can be recirculated going through the device at multiple times a day. Please note this trial should be easy one: just a submerged pump should be required and nothing in the existing line is required to be changed so this trial can be accepted by your customers easily.

For less than 200RT(TR) of the capacity, W3 model should be recommended for the trial.

Between over 200RT( TR) and 400RT (TR), W5 model should be recommended for the trial.

For more than 500RT(TR), W7 model should be recommended for the trial.

If the cooling tower can be stopped for a while and the heat exchanger can be opened, open the heat exchanger before starting the trial and again open after 10 days, 20 days and 30 days and check if the heat exchanger is started to be cleaned.

If the cooling tower cannot be stopped and is required to run for 24 hours, then the temperature difference can be criteria for judging the effects of LTIWET device.

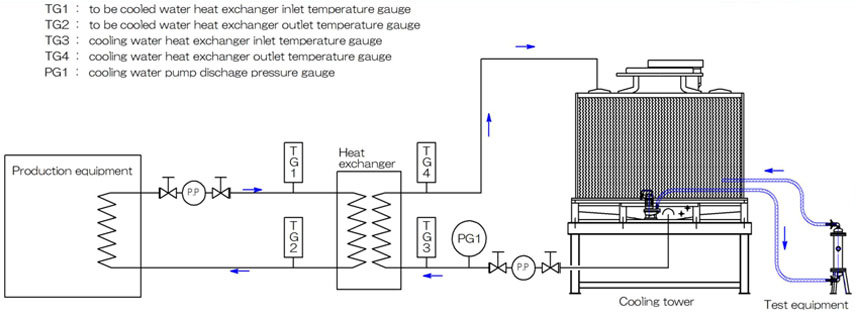

1)Check the temperature difference between TG1 and TG2, also between TG3 and TG4 before the installation of LTIWET device.

2)Check the temperature difference between TG1 and TG2, also between TG3 and TG4 after the installation and running of LTIWET device after 10, 20 and 30 days respectively

NB: The outside air temperature in the comparison above should be similar, and if a little scale is built up in the heat exchanger, the temperature difference could be much less.

Expanding the temperature difference mentioned above could show the effects that the heat exchanger has been cleaned up and the existing scales have been removed.